Spherical Roller Bearing(Large (200-430mm)) It is can be used for precision instrument, low noise electrical machinery, auto, motor and common machine and so on; It is the most widely used bearings in engineering industry. 1, Outside rollaway nest is in shape of sphere, together with the function of self aligning, thus can compensate the error caused by non-concentricity and axes deflection, but relative lean of inside ring and outside ring should not excess 3 degree.

Angular-contact ball bearings are able to support radial load and axial load. As single row angular contact ball bearings can only support axial load in single direction, matched bearing mounting is often adopted to them. As matched pairs of bearings, preload for them is more convenient. Retainer are made of brass, synthetic resins or others subject to individual bearing features and application conditions. All types bearings can be SS stainless steel bearings too.

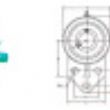

Pillow block bearings UCP 1. ISO9001: 2000 standard 2. Material: GCr15 GCr15SiMn 3. ID size: 20~160mm 4. High-end technology&top quality 5. Competitive price Greese/Oil as you requirement, such as SRL ,PS2, Alvania R12 and so on. Series SeriesUC, SeriesUCP, SeriesUCF, SeriesUCFL, SeriesUCT, SeriesUCFA, SeriesUCFB, SeriesUCFC, SeriesUCHA, SeriesSB, SeriesSALF, etc Ring Material Chrome Steel ,Carbon steel,Stainless steel Tolerance grade GB/T307.1-205 ID Size 20~160mm

Angular Contact Ball Bearings (7502B) 1. Spherical roller (21000, 22000, 23000, 24000, 29000 Series) 2. Tapered roller (30000 series and Inch Size). 3. Thrust Bearings. (50000series) 4. Pillow Block, (UCP, UCF, UCFL) 5. Low-noise deep groove ball bearing (mostly 6000 series) professional bearings factories in China. The material we mainly using Includes Chrome Steel GCR15 And high Carbon Steel GCR11. Angular contact ball bearings are able to support radial load and axial load.

Bearing Selection of the three major factors must be considered is the speed limit, required service life and is expected to absorb the workload, which is bearing the selected three performance requirements must be met.Speed limit is the maximum allowable bearing rotation speed exceeds this limit, the bearing operating temperature will continue to rise, dry lubricant, so bearing stuck, so speed limits of the selected bearing bearings intended to take more than the maximum working speed than 10% is appropriate.

Bearings running hot1, lubricating oil or grease select unreasonable, lubrication system configuration is reasonable, good heat dissipation;2, to how much the temperature, whether within the allowable range;3, pretension is too large, smaller clearance;4, precision bearings for compliance; whether there is damage;5, using the environmental impact of the bearing, such as whether the dust and other particles into the bearing; 6, bearing selection is correct,

Acoustic detection of bearing anomalies present in two ways. One is the detection method based on acoustic noise, and the other is based on the vibration detection. (A), noise detection method: the noise is less than 20db silencer based environment, the use of high-quality microphones to extract a certain distance and direction of the sound pressure bearing signal, and by a certain method to extract the abnormal sound component abnormal sound is a direct measurement method.

Bearing the seal can be divided into two categories own seal and the added seal. The so-called sealed bearings are the bearing comes into its own manufacturing unit with the sealing performance. Such as bearings with dust cover, seals, etc.. This sealed space is small, installation and removal easy, cost is relatively low. Plus the so-called bearing sealing device is installed within the end cap and other manufactured with a variety of performance seals.